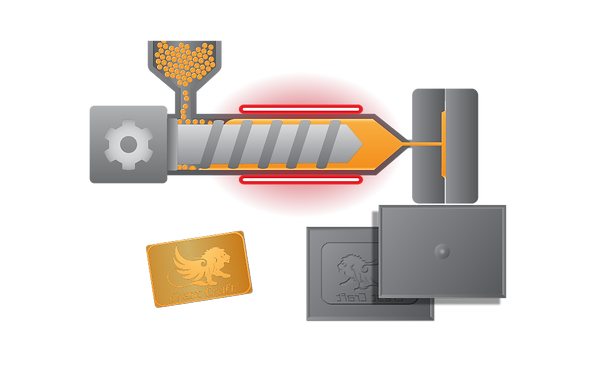

Injection Molding

Injection molding is a highly efficient manufacturing process that involves injecting molten material into a mold to produce complex and precise components with excellent consistency and repeatability. This method is invaluable for creating high-quality, durable parts for a wide range of products. Crest Craft excels in providing exceptional injection molding services, offering expert craftsmanship, state-of-the-art technology, and personalized customer care to ensure that each project meets the highest standards of quality and precision.

Image Transfer Process

Whether by sublimation heat transfer or screen printing, the process of image transfer is a efficient, cost effective streamlined process that produces beautiful, durable results.

Make Your Product Line Manifest with Injection Molding

1. High Efficiency: Injection molding allows for rapid production of large quantities of components, making it an extremely efficient manufacturing process for high-volume runs.

2. Precision and Consistency: The process ensures precise control over the shape and dimensions of each part, resulting in high consistency and uniformity across all produced items.

3. Complex Designs: Injection molding can create intricate and complex shapes that would be difficult or impossible to achieve with other manufacturing methods, allowing for great design flexibility.

4. Material Versatility: A wide variety of materials can be used in injection molding, including various plastics, rubbers, and metals of any color, making it suitable for diverse applications.

5. Reduced Waste: The process is highly efficient in material usage, with minimal waste generated, and any excess material can often be recycled, contributing to cost savings and environmental sustainability.

6. Strength and Durability: Injection-molded parts are known for their strength and durability, making excellent products and components with outstanding longevity.

7. Cost-Effective: Despite the initial setup costs for molds, injection molding is highly cost-effective for large production runs due to its speed, efficiency, and low per-unit cost, making it an economical choice for mass production.

njection molding is valued for its high efficiency, precision, material versatility, and cost-effectiveness, making it an ideal option for producing large quantities of complex and durable parts with consistent quality.